Why Cleanrooms and Sterilization Equipment Are Essential for Sanitary Napkin Safety

Design and Manufacturing of Automated Sterilization Packaging Equipment for Sanitary Napkin Production

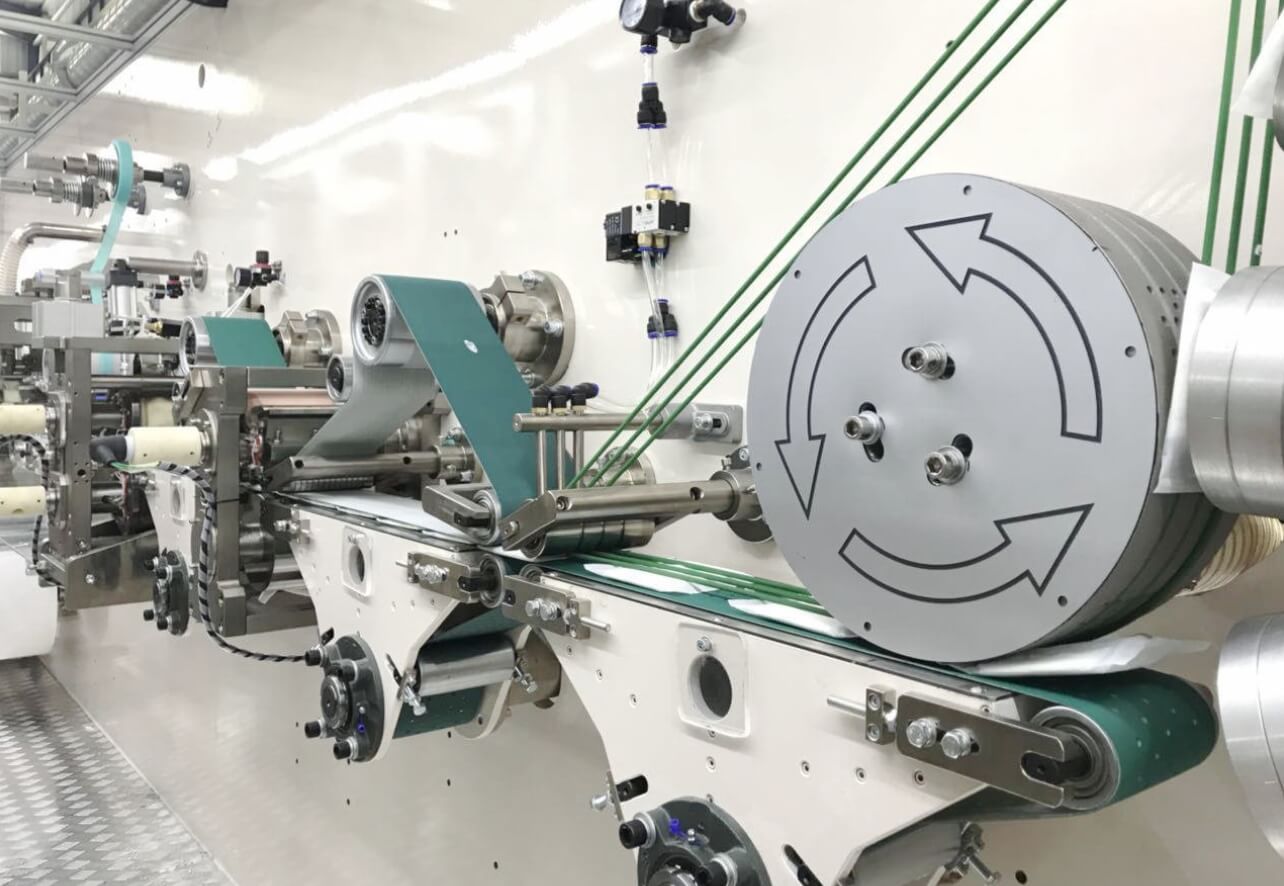

Sanitary napkins, as essential hygiene products in women’s daily lives, directly affect the health and comfort of users. With the growing global focus on women’s health and environmental protection, the production process of sanitary napkins has been continuously upgraded, especially the design and manufacturing of automated sterilization packaging equipment. This equipment has become a critical element in improving production efficiency, ensuring product quality, and safeguarding consumer safety.

Importance of Automated Sterilization Packaging Equipment

In the production of sanitary napkins, sterilization is a crucial step to ensure that the products are free from bacteria and harmful substances that could impact the health of users. The design of automated sterilization packaging equipment not only increases production efficiency and reduces human intervention but also ensures that each sanitary napkin undergoes standardized sterilization, thereby improving the overall product quality.

Sterilization packaging equipment plays a vital role in the production process. It typically integrates multiple functions, including temperature control, humidity regulation, and cleanroom management, ensuring that every step of the packaging process adheres to hygiene standards. Through automation, human error is minimized, and every batch of products meets the required sanitary conditions, thus earning the trust of consumers.

Production Environment Requirements for Automated Sterilization Packaging Equipment

To ensure the efficient operation of sterilization packaging equipment and product quality, the design of the production environment is critical. Below are key environmental requirements:

- Cleanroom and Environmental Control

Due to the strict hygiene requirements in sanitary napkin production, the design of the production facility must meet ISO cleanroom standards. Temperature and humidity must be tightly controlled to prevent microbial growth and product moisture. - Equipment Stability and Reliability

The sterilization packaging equipment needs to be highly stable and reliable for long-term operation. The precision and efficiency of the equipment reduce failure rates, ensure normal operation of the production line, and enhance productivity. - Compliance with Hygiene Standards

All materials used in the production environment and equipment must comply with international standards, such as FDA, CE, and ISO. The sterilization device should employ efficient and harmless sterilization methods, such as ultraviolet light or hydrogen peroxide, to ensure product safety. - Storage and Transportation Conditions

After sterilization, sanitary napkins must be stored in specialized areas that also meet specific temperature and humidity control requirements to prevent contamination. Finished products must be transported under conditions that maintain their stability and prevent damage or contamination.

Key Indicators and Recommendations for Choosing a Large, Reliable Sanitary Napkin Manufacturer

Choosing the right sanitary napkin manufacturer is crucial to ensuring product quality. Below are key indicators and recommendations:

- Certifications and Standardization

It is essential to verify whether the manufacturer holds international certifications such as FDA, GOTS, ISO9001, etc., which ensures that their products meet safety and compliance standards. Certifications serve as core indicators of the manufacturer’s production capability and quality management. - Technology and Equipment

The manufacturer should possess advanced technology and automated production lines, which are critical for production efficiency and product consistency. In particular, the sterilization and packaging equipment plays a major role in maintaining high product quality. - Production Capacity and Delivery Capability

The manufacturer’s production capacity should be able to meet large-scale order demands, and they should have the ability to deliver products globally. Given the fluctuations in global sanitary napkin market demand, choosing a manufacturer with flexible production scheduling capabilities is essential. - Environmental Sustainability

With the increasing demand for eco-friendly products, selecting manufacturers committed to sustainability and the use of natural plant fibers and biodegradable materials is essential to meeting environmental trends and reducing ecological impact.

SRISING Company Profile

SRISING is a professional manufacturer of hygiene products, dedicated to providing high-quality, eco-friendly, and safe sanitary napkin products to consumers worldwide. The company has a rigorous quality control system and has passed various international certifications, including FDA, GOTS, CE, ISO9001, ensuring that every product complies with global standards. SRISING has advanced production facilities in Shanghai and Guangdong, China, equipped with world-class clean, dust-free, and hygienic workshops, as well as efficient automated production lines.

SRISING continues to innovate technologically, aiming to develop healthier, safer, more skin-friendly, and higher-quality sanitary napkin products. Additionally, the company prioritizes environmental protection by researching and developing hygiene products made from natural plant fibers and biodegradable materials, meeting the growing demand for eco-friendly products.

Conclusion

The automated sterilization packaging equipment used in sanitary napkin production is a crucial component in enhancing product quality, ensuring hygiene safety, and improving production efficiency. Choosing a technologically advanced and well-managed manufacturer directly impacts the final product’s quality and market competitiveness. As the global demand for sanitary napkins continues to rise, manufacturers like SRISING are committed to continuous innovation to improve production processes and meet consumers’ higher expectations for health, safety, and environmental protection.